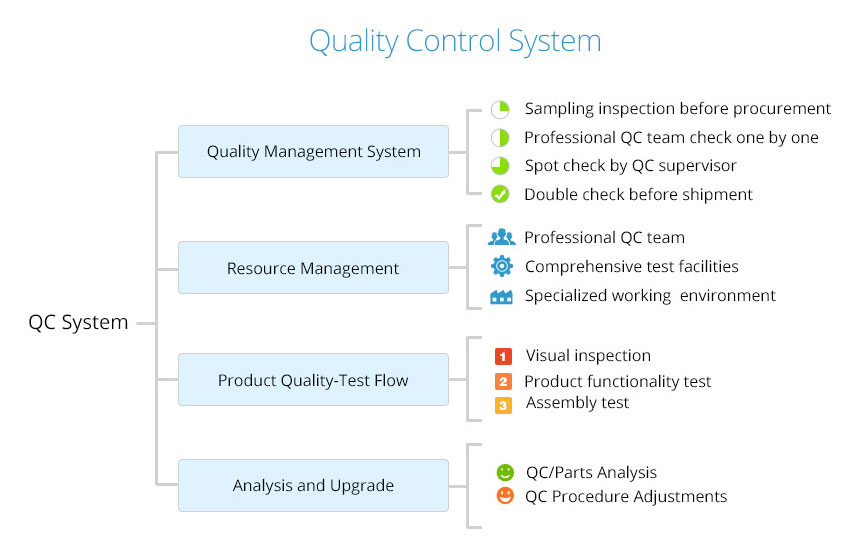

Quality Control System

HOW WE TEST

-

Visual Inspections

Qualified Standard:- No scratches or damages.

- No missing parts, such as screws or adhesives.

-

Functional Tests (Touch Screen Test)

Tools Needed:- LCD and Touch Screen Tester.

- Built-in test application (for Android phones only).

- Tester Test Standard: Draw diagonal straight lines on the screen. The lines should appear without any misalignment, breakage, or distortion.

- Application Test Standard: The software should indicate a pass.

-

Functional Tests (Small Parts Tests)

Tools Needed:- Relevant OEM Test Modules.

- Other related devices, such as earpiece (for audio flex test), data cable and charger (for charging port test), multimeter (for tests on loudspeaker, ear speaker, and vibrating motor).

- Module Test Standard: The parts should function normally.

- Multimeter Test Standard:

- Loudspeaker resistance should be between 6~10 ohms.

- Ear speaker resistance should be between 27~32 ohms.

- The vibrating motor should vibrate or rotate when supplied with 1.5~4.2V DC power.

-

Functional Tests (LCD Display Test)

Tools Needed:- LCD and Touch Screen Tester.

- Built-in test application (for Android phones only).

- Tester Test Standard: No more than 2 dead pixels (pixel diameter must be less than 0.15mm).

- Application Test Standard: The software should indicate a pass.

-

Functional Tests (Battery Test)

Tools Needed:- Multimeter.

- DC Power Supply.

- Probe Leads.

- Voltage Standard: 3.7V.

- Normal Charging Standard: The multimeter should display the correct charging value.

- Normal Discharge: The device should power on normally after assembly.

-

Assembly Tests

Tools Needed:- Screwdriver.

- Tweezers.

- Other related devices, such as RF Test Equipment, NFC Test Device.

- The assembly should work normally on OEM Test Modules.

- There should be no cosmetic or functional incompatibility on OEM Test Modules.

Quality Guaranteed through Our Industry-Leading QC Standard

Latest update: November 19, 2024