- US Dollar ($)

- Australian Dollar ($)

- Canada Dollar ($)

- Swiss Franc (CHF)

- Czech Koruna (Kč)

- Danish Krone (kr)

- Euro (€)

- British Pound (£)

- Hong Kong Dollar ($)

- Israel Shekel (₪)

- Japanese Yen (¥)

- Mexican Peso ($)

- Norwegian Krone (kr)

- New Zealand Dollar ($)

- Philippine Peso (₱)

- Polish Zloty (zł)

- Russian Ruble (Р)

- Swedish Krona (kr)

- Singapore Dollar ($)

- Thai Baht (฿)

- Chinese Yuan Renminbi (¥)

- US Dollar ($)

- Australian Dollar ($)

- Canada Dollar ($)

- Swiss Franc (CHF)

- Czech Koruna (Kč)

- Danish Krone (kr)

- Euro (€)

- British Pound (£)

- Hong Kong Dollar ($)

- Israel Shekel (₪)

- Japanese Yen (¥)

- Mexican Peso ($)

- Norwegian Krone (kr)

- New Zealand Dollar ($)

- Philippine Peso (₱)

- Polish Zloty (zł)

- Russian Ruble (Р)

- Swedish Krona (kr)

- Singapore Dollar ($)

- Thai Baht (฿)

- Chinese Yuan Renminbi (¥)

- Shenzhen, Room 210, Building 2, 1970 Technology Town, MinKang Road, Longhua District,

- +86 755 2774 3687 (the call is free)

- Mon-Sun 9.00 - 18.00

- Sales@unionrepair.com

- View on map

+86 755 2774 3687 Call Monday - Friday: 9:00 AM - 9:00 PM (UTC+8)

Email Sales@unionrepair.com

Address

Tony | Sales Manager

Tony@unionrepair.com

English

More Professional Battery Testing on UnionRepair

More Professional Battery Testing on UnionRepair

Today we’d like to talk something about testing iPhone battery. I believe that some of our customers might had battery issues already like, the battery cannot be fully charged or suddenly dead when using your iPhone or it is losing power abnormally fast, etc. We’ve had same problems as described and it has brought us troubles like losing customers and some bad reviews which is very adverse to our business.

To solve the problem and help us get rid of the dilemma, there is a professional battery tester needed. Therefore, we bought this big machine months ago and we’ve been testing batteries with it for months. It really helps a lot. Now I am going to tell you how we test with this machine and what we can learn to decide whether a battery can be considered as qualified with its capacity and voltage.

First, let us take a look at the machine. Actually, it is more like a metal cabinet with 10 working devices inside of it, each device has 8 testing panels which comes with battery connecting board and these boards support iPhone battery from 4s to the X. By the way, the machine enables us to test different batteries at same time which really save us lots of time.

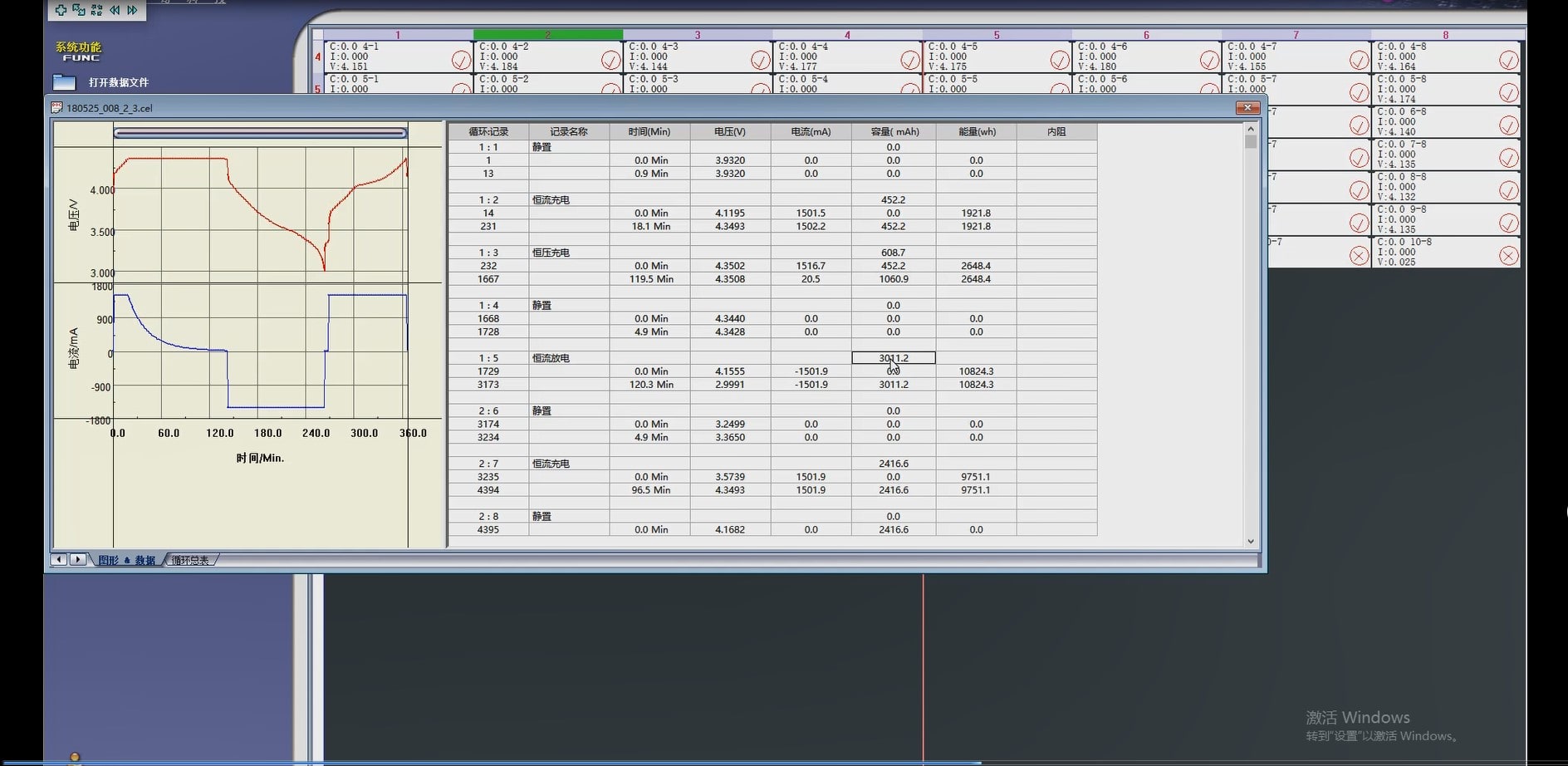

Secondly, the machine must be working with a computer to record real-time data that we need for battery testing. There is a special designed program to help us analyze batteries and help us record data like capacity、voltage and current. Each time before we start, we will need to do preparation work such as setting testing steps, setting testing parameters, etc. (For more details please check our video at https://www.youtube.com/watch?v=FLglFYwsnTA&t=118s ). And it will take us 6-8 hours to record the real-time data such as battery capacity、charging and discharging voltage/current.

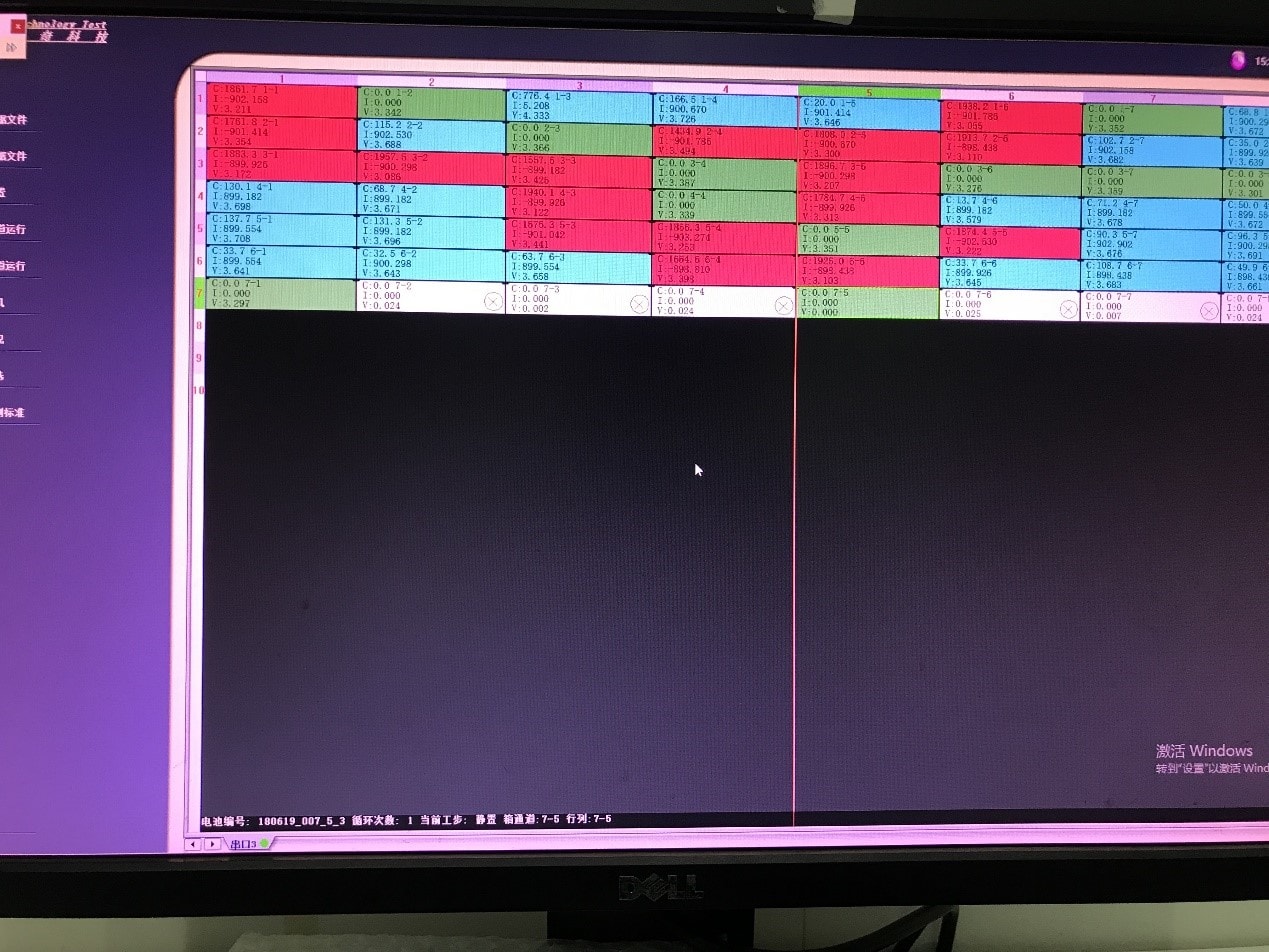

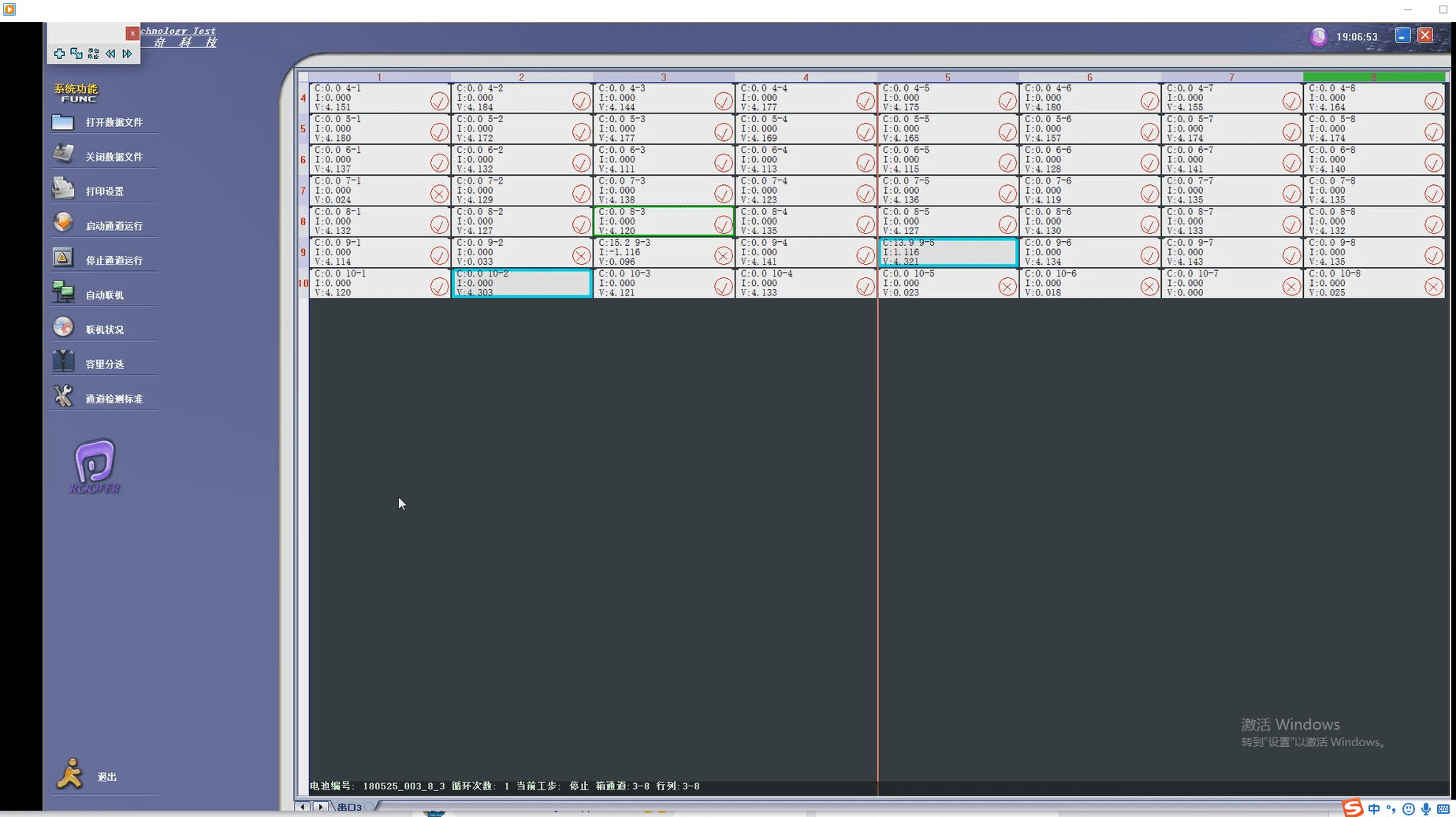

By starting the program, you will see there are 80 cells and each cell is a one to one correspondence with the testing panels. And after we finished the test, you will see √ and × marks in the cell also some different colors as well. We’d like to explain you what the meaning of these different marks is. √ means those batteries has finished the testing steps, however it does not mean they are good quality, we still need to make a further inspection by opening its data analysis chart. X means those has not finished the test yet or simply means there are no batteries on the testing panel. Those different colors are referring to different testing steps.

According to our technician, if the capacity of a battery ranges between 98%-102% of its design capacity, we may say the battery is original quality, if it ranges between 95%-105%, the battery can be considered as copy ones. We don’t accept low capacity neither the extended capacity batteries. That is our battery testing standard.

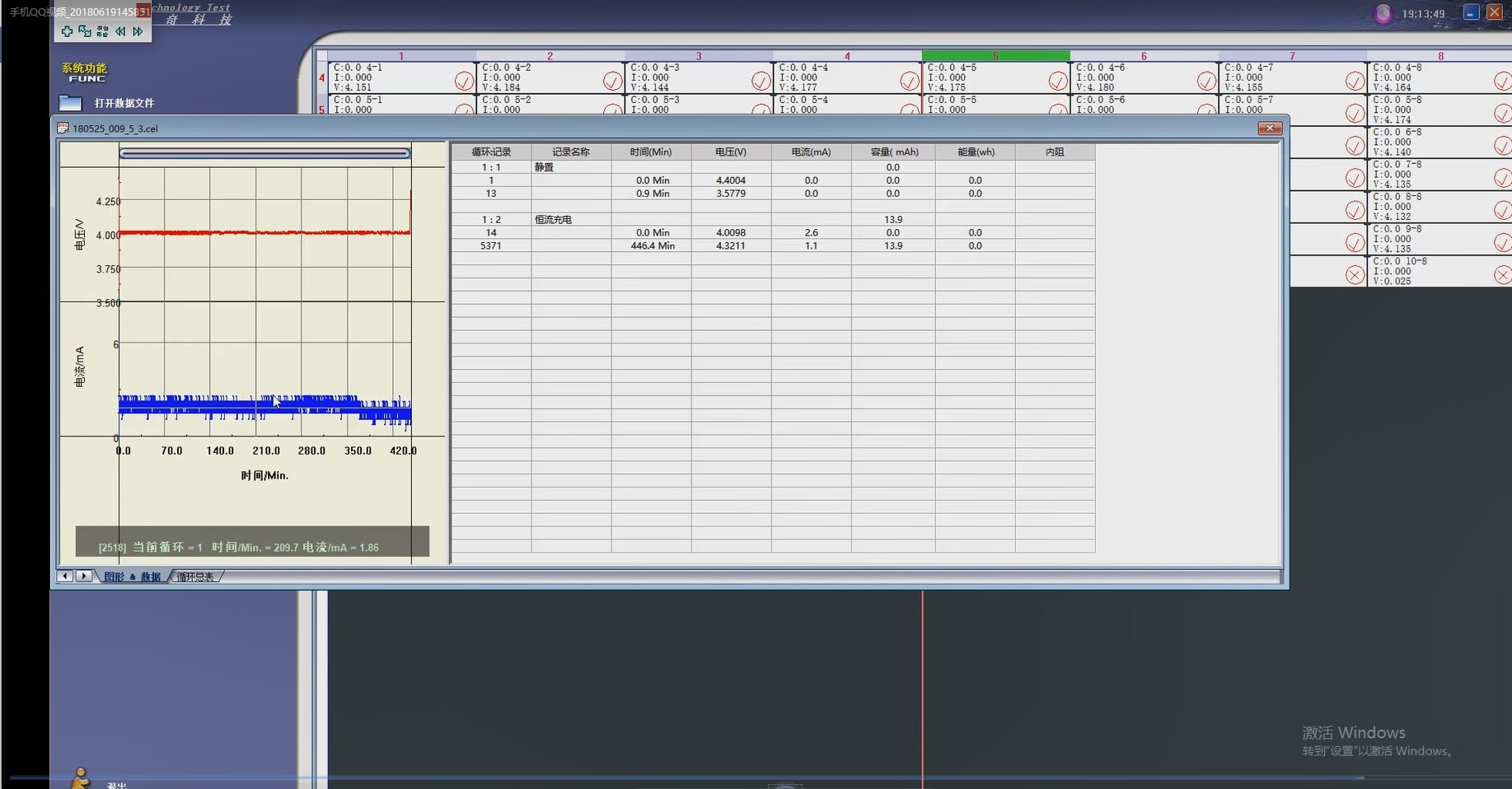

Here are some screenshots of the testing results.Unstable charging current and voltage makes the battery stopped at the first testing step.

1, Unstable charging current and voltage makes the battery stopped at the first testing step.

2, Cells of different colors show the batteries under different testing steps.

3, Checking the capacity of iPhone 7.

4, Cells of × and √

Two Months have gone and through our effort there is no complaint about our iPhone batteries by far. We believe that by checking iPhone batteries with this machine, we are able to control the quality of each battery and there will be no more dead batteries or battery with low capacity or some other issues like before. And we’d be very appreciated if there is someone can make some reviews about our battery. Please feel free to contact us if you have any questions: sales@unionrepair.com

Our YouTube channel: https://www.youtube.com/channe...

Like our Facebook page at: https://www.facebook.com/unionrepaircom/

- Room 210, Building 2, 1970 Technology Town, MinKang Road, Longhua District, Shenzhen, Guangdong, 518000, China

- +86 755 2774 3687

- Mon-Sun 9.00 - 21.00

- Sales@unionrepair.com